How to wire the board to board connector

First, wind the solder wire on a support rod with a diameter equivalent to the long lead pin of the board-to-board connector, and then cut the solder wire on the support. After the solder wire is cut on one side, a solder ring with openings on both sides can be seen , Then flatten the solder ring, put one or more flattened solder rings on the bottom of the long lead pins of the connector, and then lay it flat and want to blow hot air into the connector to heat the solder ring. The hot air melts the solder ring and causes It enters between the PCB board and the long lead pin of the connector. After the solder wire connector is completely melted, stop the hot air blowing, and wait for natural cooling. After the solidified solder, the long lead pin of the connector is connected to the PCB board. Just connect it.

Electronic connectors are indispensable parts in the electronics industry. They not only allow current to flow in the circuit, but also facilitate maintenance and replacement, simplifying the production process. As electronic connectors become more and more sophisticated and miniaturized, the requirements for electronic connectors are also higher. High reliability, small size, high transmission performance, etc.

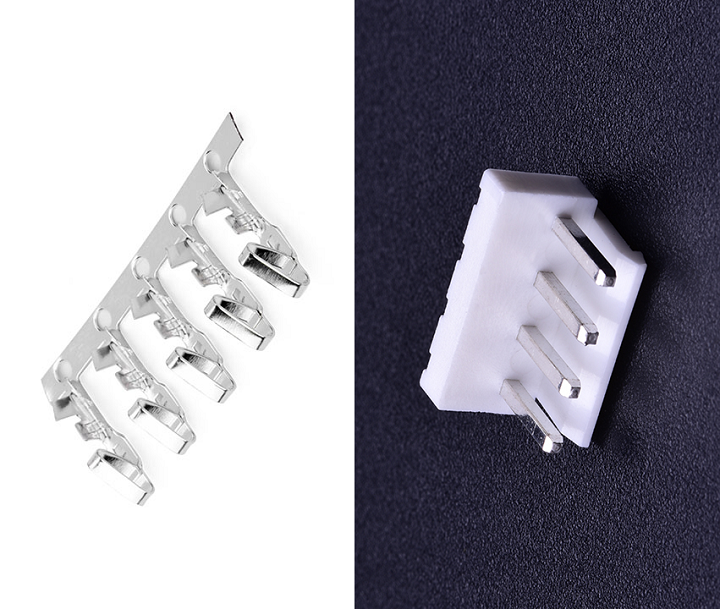

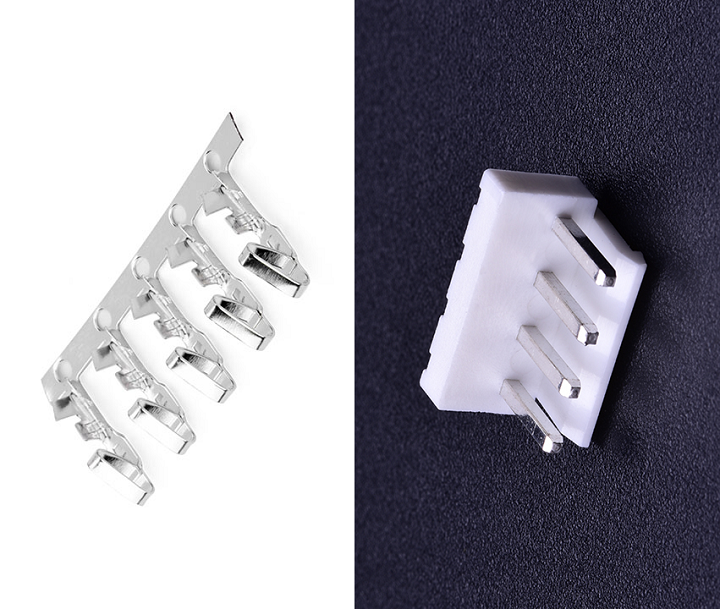

The key part of the electronic connector is the terminal. The terminal is equivalent to a small connector, which connects some devices with the same or different performances together to ensure that some components can run smoothly or that the current can flow smoothly, so that the entire device It can be operated. The materials of electronic connectors are mostly different, because the properties and functions of the places used are different, so the material selection will be different. Some need high temperature resistance, and some need corrosion resistance. In short, the selection of materials is based on the specific connector conditions. Electronic connectors play a role in the entire system. Therefore, electronic engineers not only pay attention to the chip, but also other electronic components when designing and choosing. of.

In actual operation, not every kind of electronic connector is suitable, and various situations will happen frequently. For example, the use of cheap connectors will eventually pay a high price, and even regret it, causing the system to fail to operate normally and product recalls. , Product liability cases, circuit board electronic connectors are damaged, reworked and repaired, which will then cause loss of customers.

A few years ago, in order to reduce costs, wire-to-board and board-to-board manual welding was continuously unavailable for many Chinese LED lighting manufacturers. Nowadays, to deal with the heat dissipation performance of LED lighting, aluminum substrates with better thermal conductivity have gradually been used Small use, such as continuous manual soldering, will greatly improve the quality of the connection risk. As we all know, the soldering process requires an optimal soldering temperature. During manual soldering, when the soldering iron tip of the industrial connector is placed on the pad of the aluminum substrate, the solder joint Due to the superior heat conduction function of the aluminum substrate, the temperature cannot rise quickly, and it is easy to form hidden quality problems such as false welding, false welding and cold welding, which seriously affect the quality of the product.

In response to these problems, a series of wire-to-board and side-insertion board-to-board wire-to-board connectors for solid-state lighting suitable for high-speed surface mount (SMT) have been newly developed. The shell is made of low-temperature plastic, which fits the common reflow of LED lighting module manufacturing. Welding process request, wire-to-board board-to-board connector can stop surface mounting together with LED, SMT and through-hole pull-out lighting wire-to-board connector, whether it is popular plastic board or aluminum substrate, can provide disease Fast and reliable cable termination, this small size and low height SMT one- and two-position wire-to-board connectors are very suitable for LED light bar interconnection, lighting controllers and other applications using pull-out wiring.

The wire-to-board connectors are fully waterproof and dust-proof. They are available in wire-to-wire and wire-to-board versions. They extend the pins of the popular sealed IP67-level wire-to-board connector, including D-Sub, USB , HDMI, wire-to-board and wire-to-wire wire-to-board connectors, and support low-level signals and power requirements up to 300V.

The integrity of the electronic signal of the product can be ensured through external polarization, thus eliminating the possibility of plugging and unplugging, and its line terminals are manufactured in a true crimping-type header connection processing plan. The product's wire seal When the component is crimped to the cable when the contact header is crimped, it will be assembled to each circuit in the casing afterwards, without internal wire sealing.

The substantial increase in automotive infotainment and safety options is a catalyst for vehicle manufacturers that require suppliers to provide smaller interconnected products. Design engineers must install more electronic installations in the opposite space and use smaller pins. And terminal size, the non-sealed wire-to-board system allows equipment manufacturers to install circuits in a tighter space, while reducing costs and maintaining functionality, safety and reliability.