What to pay attention to when choosing terminal connectors

The current terminal connector applications are very common, especially in the industrial field. Different types of terminal connectors have different application requirements. When producing terminal connectors, some factors also need to be paid attention to at all times. Then Lilu Let me explain to everyone through the editor of the connector.

It should be known that as an accessory product of industrial production electrical components, the main function of the terminal is to facilitate the connection of the wires. Therefore, in the process of industrial development, it is also divided into the range of the connector connector, which is also called the terminal connector. It is said that it plays an important role in industrial production, and it plays the same role as a connector. It is not only convenient for production, but also conducive to improving production efficiency as the main purpose.

In addition, according to the process of industrialization, wire connection and signal transmission have already been implemented, but how to ensure the transmission process is the purpose of designing the terminal, which is the important component role of the terminal connector.

It should be noted that the terminal connector mainly completes the transmission task by the tightness of the terminal itself in the mother body. The combination of the terminal inserted into the mother body and the mother body is an important criterion for considering its performance, and it is also the main way of performance. If the combination is not tight, then there will be failures, affecting production and other factors.

Most cable assemblies used in motion control systems require some type of interconnection device to transmit signals from the cable to the motor or drive. So what kind of connector is suitable for industrial motion control systems.

Connectors commonly used in industrial motion control systems are mainly used for sensors, actuators, fieldbus and industrial Ethernet in factory automation applications. They usually need to have IP65, IP68 and IP69K protection levels to ensure that they can be washed and corrosive environments use.

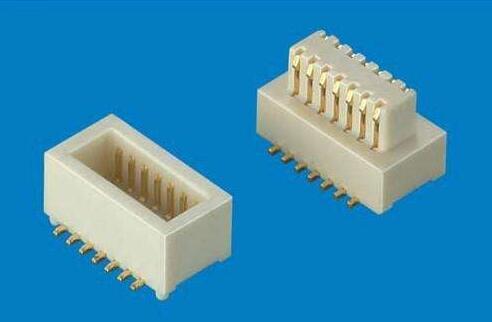

It should be known that high-speed micro connectors are becoming more and more common in industrial automation compact designs that require letter electronic connector number density, electrical performance and mechanical reliability. Modular connectors with locking systems, micro connectors and Heavy-duty connectors can provide reliable connections even in high-vibration environments. These designs must provide mechanical strength and vibration resistance in the power, control and signal circuits in demanding motion control systems.

If the connector is in the case where the machine must transmit power and data from the fixed structure to the rotating shaft, the connection usually relies on slip rings. They are common in wind turbines and packaging machinery where there is continuous rotation. Slip rings replace industrial Motion cables provide power and data in these rotating devices.

Many industrial automation networks require large amounts of data at extremely high speeds, but they usually operate in harsh environments and narrow spaces, making this require compact connectors with a pitch of 1.27 mm [0.050 inch board to board] or smaller , And the high-density miniature connector has a higher speed capability due to its design flexibility.

Connectors require correct insertion and removal forces that greatly affect the pressure and productivity of workers. When a lower pound force can be used to create normal contact, the task of the worker may become easier. Insertion force is the coefficient of friction, wear resistance and other mechanical A factor of variable, connector design and materials play a key role in reducing friction. When pin headers involve 10 to 12 contacts, the force will increase by 18 pounds or more for connector insertion and removal, high peak Insertion force can cause many problems, such as CTS, and recent connector design solutions have solved these problems.

Advanced connector design can be used to improve standard connectors that have not changed for decades. When encountering a higher number of connectors due to more signal and power lines in more complex devices, workers can extract the mother from LI Benefits from F terminals. In many cases, it is worth studying the benefits of LIF connector design compared to applying lubricant to terminals to reduce insertion and extraction forces.

The benefits of the new design may include: “click” sound and tactile feedback when the connector is engaged, so that production workers know when to stop applying force, and provide visual keys to avoid jamming the connector in the wrong direction, such as The introduction of rounded edges and connectors under the shell to further reduce assembly problems.